Wire Mesh Baskets for Transport & Shipping

Custom Wire Baskets for Transport & Shipping

Wire Baskets for Parts Transportation

Use Cases

- Automotive

- Aviation & Aerospace

- General Manufacturing

- Industrial Manufacturing

- Medical/Medical Device Manufacturing

Features

Our design and manufacturing process allows us to offer many standard and custom features and additional services as required by your application. We frequently manufacture unique lids and dividers to keep components secure during coating and finishing processes and transport. We have also designed and implemented new grid configurations, specialized welding processes, and other innovations to meet our customers’ needs.

Materials We Use

304 Stainless Steel

316 Stainless Steel

330 Stainless Steel

Carbon Steel

Our Work

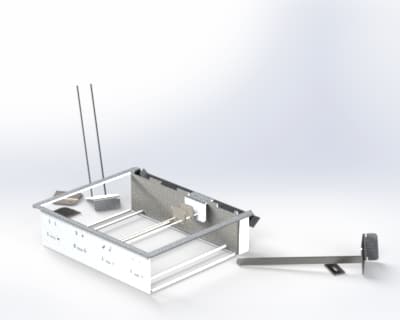

Stainless Steel Tray and Carrier for Clipper Blades

This customer manufactures clipper blades and contacted Three M Tool about creating a custom stainless steel tray and carrier system to hold the blades through a full rotation cleaning process, a heat treating process, and a chemical dip.

Expanded Metal Tote Baskets

An industrial plant customer reached out to the TMT team to custom manufacture strong, inexpensive expanded metal tote baskets to stack and store parts. The baskets needed to be rugged enough to be stackable during loading, with handles that secure the stacked baskets but are easy to grab and lift.

FAQ

Yes, part protection is very important when the baskets are used to clean and transport parts. Most of the time the parts will need to be secured in a lid or grid design, be stackable, and be strong and durable to prevent damage when moving through transport.

Let’s talk about your needs.