Wire Mesh Baskets for Heat Treating & Normalizing

High-Temperature Wire Baskets

Custom Wire Baskets for High Heat Applications

Use Cases

- Aerospace

- Engineering & Manufacturing

- Automotive Manufacturing

- General Manufacturing

- Medical/Medical Device Manufacturing

Features

Materials We Use

304 Stainless Steel

316 Stainless Steel

330 Stainless Steel

Carbon Steel

Our Work

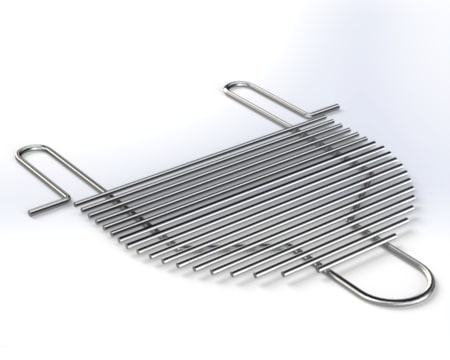

Formed Stainless Steel Grate for Barbecue Grill

Our customer produces custom, high-end patio accessories including custom barbecues. They approached Three M Tool to manufacture a grate to fit their custom barbecue’s unique shape and intricate height adjustment mechanism while withstanding the high temperatures and corrosive effects of grilling.

Custom Wire Basket for Oddly-Shaped Parts

Our customer needed a stainless steel wire basket to hold cast aluminum parts throughout a vacuum impregnation process that cleans the parts, coats them with chemical sealant, spins them at several hundred RPMs to remove excess sealant, and cures the sealant with a hot air blast.

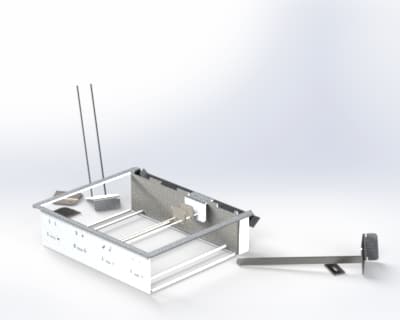

Stainless Steel Tray & Carrier for Clipper Blades

Our customer, a clipper blade manufacturer, needed a stainless steel tray and carrier system to hold blades through a full-rotation cleaning process, heat treating process, and chemical dip. The system needed to secure the parts, be easy to load, and able to withstand rough conditions during the various processes.

FAQ

Most of our customers are looking for a heat treating basket that can be used throughout their facility and move from operation to operation. For that, we would recommend using the 330 SS material grade, as it can withstand the most heat while providing the flexibility needed to be moved around.

Let’s talk about your needs.